Electric car battery repairs and health checks: how to keep thousands of EVs on the road

The truth about EV battery repair and why understanding state of health could revolutionise the electric-car market

It’s fair to say there remains a lot of scepticism and concern surrounding electric cars, primarily the longevity and repairability of their battery packs – and it’s sometimes for good reason.

EV batteries are essentially much larger versions of the lithium-ion units in your smartphone, so they contain rare-earth metals and are thus expensive and energy-intensive to produce.

In 2024, the average manufacturing cost per kilowatt-hour for a brand-new battery pack was roughly £110 – slightly less for one utilising LFP (lithium ferrophosphate) chemistry – which translates roughly to £6,500 for your run-of-the-mill electric car with a 60kWh capacity. That’s not even considering the cost of labour, which can dramatically elevate things further – potentially as high as £20,000 or more in total.

This wouldn’t be so bad if batteries were easy to repair, but very few average mechanics have sufficient knowledge of battery chemistry, let alone the correct and safe procedures, to work on one. Therefore, it’s easy to see why the likes of insurance firms (and thus the general public) have long perceived EV batteries as irreparable – or that the work is not financially viable.

But this doesn’t have to be the case, so we visited Autocraft EV Solutions in Grantham, Lincolnshire, to find out how batteries can be repaired and why the latest technology could not only give consumers a better insight into their car’s state of health, but potentially also reduce electric-car depreciation simultaneously.

What is EV battery State of Heath?

Battery state of health (SOH) is a pretty self-explanatory term in the sense that it’s a measure of an EV lithium ion pack’s condition relative to its performance when new. However, while it’s easy to simply regard this as a representation of how much less energy a battery can store compared with when it first rolled out of the factory, it’s a little more nuanced than that.

Mike Hague-Morgan, Autocraft’s co-owner and executive director, explains that when assessing the condition of a battery pack, there are two main areas the team considers: capacity (how much energy the battery can store) and resistance (how easily the battery accepts the flow of electricity in and out).

Once figures are obtained, Autocraft can compare them with a digital twin of the car in question to see what the parameters should be. This can be formulated to give a state-of-health figure, although this is typically somewhat arbitrary, because different organisations and individuals won’t necessarily use the same data.

At the time of writing, there are some firms that sell so-called ‘dongles’, which can directly plug into the car and retrieve some of this information. However, the likes of Autocraft go much more in-depth in this regard, with Hague-Morgan likening the firm’s approach to an MRI scan, rather than just a simple X-ray.

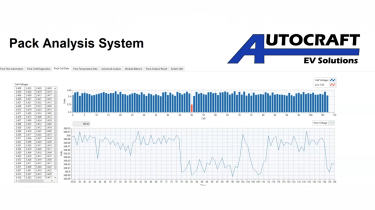

Hook up a battery to Autocraft’s OptEVizer system and the team can identify irregularities in each battery cell down to fractions of a millivolt, thus not only diagnosing the problem at the source, but also recognising any developing issues before they have any real impact on the performance of the battery pack.

What is a battery passport?

Obtaining this information isn’t easy, because it requires specialist kit that isn’t necessarily readily available. And with EVs typically not making the same indicative sounds and rattles as an ICE car, buying a used model can feel perilous.

Autocraft’s engineering and quality director Dr Sara Ridley admits: “While I’ve been an engineer for many years and can identify a rattle in an ICE car, even I struggle to tell if there’s something wrong in an EV on my own.”

Yet the advent of battery passport tech should make this information more accessible than ever, something that’s hoped will give buyers greater confidence when taking the plunge on an older EV.

Battery passport tech must be accessible via a QR code on the pack itself, or somewhere else within the car, and is designed to indicate the battery’s state of health, which would be updated when service or maintenance work is completed.

The passports will also provide details such as each unit’s composition and recycled material content, disassembly instructions, plus data on supply chains and carbon footprints. All this will be based on parameters that are yet to be defined.

Will the UK get battery passports?

Battery passports will be required for all new electric cars in the European Union before 2027. However, despite claims from Labour prior to the General Election that it would also mandate passports if it got into power, all the Government could tell us for now was that it’s “committed to the circular economy transition”.

Dr Ridley says she has been recruited as part of a Government task force to consult on the issue, adding: “We strongly support the concept of battery passports. Yet they need to be maintained over time, and logging repairs is part of that.”

Can EV batteries be repaired?

Yes, batteries for EVs can be repaired or ‘remanufactured’, although doing so isn’t easy, because there aren’t very many people trained to do so. To work on an EV’s complex lithium ion batteries, one must at least have attained the relevant Government-defined Level Four training qualifications. That’s not to mention having the appropriate equipment available.

All of this makes the cost of carrying out work incredibly high, resulting in many batteries being written off by either the maker or insurer if there is even just a small hardware issue detected.

Autocraft’s own research and experience when it comes to battery warranty failure suggests that as many as 92 per cent of modules within a battery pack are typically still operational following the uncovering of a fault. With each module typically comprising 12 cells and newer EV batteries usually employing 36 or more modules, only one of these needs to be replaced on average in order to restore the EV’s state of health to a normal level for its age.

‘For its age’ is the key phrase, because even Autocraft’s experts can’t restore a battery to 100 per cent of its original capacity – and that’s not down to a lack of skill. The new module needs to be balanced to match the chemistry of all of the others in the cell, but even then, due to the chemical reactions inside a battery pack which are responsible for the ageing process, full capacity will never be achievable again unless all the cells are replaced. At this stage, you may as well install a new battery.

Still, Autocraft says it can restore capacity to well over 90 per cent in most use cases and even after dissecting then reassembling the battery, can uphold a manufacturer’s original warranty.

Local garage EV repairs

Autocraft currently remanufactures 1,500 EV batteries a year, with capacity to extend this to 4,000. This makes it one of the world’s leading firms in this regard, but the caveat is how little knowledge and skill there is out there in this field.

Yet you may soon be able to get your EV battery remanufactured in much the same way at a local garage. This is because Autocraft is working on renting/franchising its patented equipment and processes out to manufacturers and by 2028, independently owned garages.

Along with the OptEVizer battery diagnosis machine, Autocraft has developed a system in which technicians can work on a battery. The Revive Workshop takes individuals step-by-step through the process to vastly reduce the risk of error. It also shuts off and sounds an alarm if any noxious gases are detected, providing an additional level of safety.

Not all EV batteries are reparable in this way, however; Teslas, for example, utilise resin rather than welds within their batteries which, in some cases, can make them difficult, if not impossible to remanufacture. But with more and more brands turning to easily removable cells and modules, it’s just a case of reverse-engineering each car’s battery pack and programming it into the system. “We’re not going to get all of the market – that’s impossible,” Hague-Morgan admits. “We just want the public and industry to embrace the concept of remanufacturing.”

Repair or recycle?

But why repair a battery when you could simply recycle it and make a new one? Firstly, there’s the price. Autocraft says that remanufacturing even now costs on average about half the price of buying a new battery, with the goal being to bring the price to less than 5,000 Euros (£4,330) by 2030.

That’s around the time that most EVs sold today will be falling out of their warranty period, with the reduced cost of remanufacturing having the potential to boost residual values. This in turn would bolster the new and used-car markets, because it would make stepping into an older EV a much less precarious prospect.

There’s also the environmental element. Recycling batteries is energy intensive and even then, many of the materials won’t be of a high enough grade to be reused in the same way. Plus there’s the process of actually manufacturing a new battery, which results in the creation of thousands of tonnes of CO2 equivalents.

Battery recycling is still necessary for a circular economy, but as Hague-Morgan says: “Every battery will need recycling at some stage, but if only one module needs replacing, why do it now?”

Typically, battery performance drops off a cliff once it falls to 60 per cent of its original capacity, but with maintenance and remanufacturing, it can take years and hundreds of thousands of miles to reach this stage, after which it’ll be recycled. Autocraft says a battery can be remanufactured several times, but it also points out that things get increasingly expensive as more modules fail.

Autocraft’s remanufacturing process also involves stripping pre-existing batteries for parts and, given that not every repair will be the same, one harvested battery can facilitate the repair of dozens of others.

All of this ultimately comes down to education. While it’s easy to view EVs as incomprehensible space-age tech, the transparency allowed by the likes of battery passports should bring understanding and peace of mind to consumers.

By 2033 Autocraft expects more than 2.6 million battery packs to fail prematurely – not due to unreliability, just simply because more of us will be driving EVs and thus statistically there are more units that could possibly fail.

Such an influx means that if we wish to fulfil the sustainability aims of the electric transition, we also need to stop viewing EV batteries as disposable components. If an issue does arise, you wouldn’t think of immediately swapping out your engine if you were in a petrol or diesel car, so why should it be any different for an EV?

Now you can buy a car through our network of top dealers around the UK. Search for the latest deals…