LT230: The best ever transfer box?

It’s still the hero of Land Rover’s 4WD system after decades of service, thanks to basic and robust engineering

The LT230 is the most prolific Land Rover transfer box, and it’s certainly stood the test of time and survived arduous use. Extreme off-road driving and heavy towing can have a detrimental effect on most drivetrain and suspension components, but the transfer box usually seems to hold out against the odds, only succumbing to relatively minor issues.

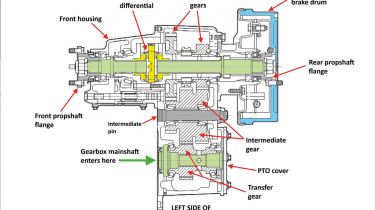

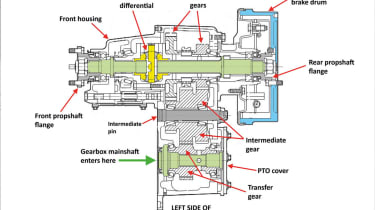

From an engineering point of view, the transfer box isn’t rocket science. It’s basically one gear set transferring the drive from the gearbox across to the right of the vehicle and then splitting the drive fore and aft to the front and rear propshafts. A differential (which is similar in design to an axle differential) sits effectively between the front and rear output drives.

It might be conventional engineering, but the fact that this design stayed in business from the One Ten of 1983 to the Discovery 2 which finished in 2004, and still lives on in the current Defender, is testament to brilliant design and manufacturing. That’s 32 years, and it still hangs together despite masses of extra torque being put through it by modern electronically performance-tuned and re-engined Defender specials. In fact the original transfer box principle, albeit without permanent four-wheel drive, dates back to the Series I of 1948.

How it all works

The transfer box is the heart of the beam axle Land Rovers’ four-wheel drive system. It transfers the drive (from the gearbox) across and out at the front and rear of the transfer casing to drive the propshafts to the front and rear axles. Unlike the earlier transfer boxes on Series Land Rovers which had rear-wheel drive and manually selectable front drive, the LT230 provides permanent drive to both axles, thanks to its integral differential.

Centre diff

A so-called centre differential inside the transfer box allows the relative speeds of the front and rear propshafts to vary, thus allowing the front axle to rotate faster than the rear, which it needs to do when turning a corner. The downside of the centre differential is that, if a wheel on one axle loses grip and spins, all the transmission torque will be sent to that wheel (it takes the path of least resistance). So, the axle that does have grip doesn’t receive any drive, and the vehicle is stuck. That’s where the transfer box’s centre diff lock comes in. Operated by the short lever in the cab, it locks the differential so that both propshafts rotate together, and are no longer independent of each other. So, if the rear axle now loses grip, the front axle will still be driven, keeping the vehicle moving(usually). As diff lock lever is used, its linkage operates a selector fork, which moves a dog clutch on the centre diff’s shaft to engage with a gear on the front output shaft, locking both drives together. Centre diff lock is intended for off-road use on loose ground where the tyres will slip a little to accommodate the difference in front/rear axle speeds when cornering. It should not be engaged on the road, or other firm surface, because the tyres are unable to slip, resulting in high stress in the driveline (otherwise known as transmission wind-up).

Hi and low ratios

As we know, the transfer box also provides the choice of high or low ratio gearing, selected by fore and aft motion of the same lever as is used for difflock. Diff lock works in either ratio, and also works with electronic traction control (if fitted). The transfer box is, of course, driven by the gearbox mainshaft which protrudes into the transfer box casing to drive the transfer gear. This, in turn, drives the intermediate gear, which continually drives the high and low ratio output gears on the right-hand side of the transfer box. These ratio gears rotate on a splined hub on the centre diff’s rear shaft. When the ratio lever in the cab is moved, high or low ratio is engaged by a selector fork as it locks the chosen gear to the centre diff’s rear shaft.

Transfer box types

There have been several incarnations of the LT230 transfer box since it was first introduced on the pre-Defender One Ten model to provide permanent four-wheel drive via its centre differential. All versions share the same basic design and external dimensions, and they also share a similar low ratio (3.2:1 on Discovery for instance). The high ratio gears vary according to the vehicle model, with Defenders generally having a lower ratio than Discovery models. Typically, an early Defender would have a high ratio of 1.41:1 and a Discovery would have 1.21:1, though there are exceptions. Remember, the lower the ratio number, the higher the gearing.

LT230R was fitted to a few early utility models and has the lowest high ratio of all, at 1.667:1 (same ratio as the LT95 combined gearbox/transfer box fitted to early V8 utility and Range Rover models)

LT230T is the most common variant, fitted to 5-speed and some auto Range Rovers up to 1989, Ninety, One Ten, and Defender (except 4-speed V8s), and Discovery 1. Post 1989 Range Rovers had chain-driven Borg Warner transfer boxes.LT230Q was fitted to Td5 Defenders onward, and is slightly quieter in operation (hence the Q) thanks to different gear geometry, more teeth on the gears, and improved bearings.

LT230SE the SE version was fitted to Discovery 2. It is similar to the LT230Q and has the same gearing ratios, though the torque handling capacity is higher. There are subtle internal changes such as a selectable spacer (replacing the collapsible type) for setting the intermediate gear bearing preload. The front output flange and mud shield is improved, and Discovery 2 model-specific changes include absence of speedo drive gears (D2 uses an electronic sensor), and the diff lock lever was removed and/or the diff lock mechanism itself, depending on production date.

Earlier boxes

As mentioned, the LT230 gear principle is derived from earlier transfer boxes fitted to Series models, which mostly had permanent rear-wheel drive only, with manually selectable front drive (all Series vehicles are in permanent four-wheel drive when low ratio is selected). But permanent four-wheel drive appeared first on the Series I between 1950 and 1954, though that was achieved using a freewheel device on the drive to the front axle. Permanent four-wheel drive re-appeared in the Series III Stage One V8 model (1979-85) using the same LT95 combined four-speed gearbox and transfer box unit as the early Range Rover, with its vacuum operated centre diff-lock

Identifying the transfer box

When buying components or considering a ratio change we need to know which LT230 transfer box is fitted, but transfer boxes tend to get swapped around as used boxes replace worn units, or vehicles are re-geared. The ratio of the transfer box may be shown on a label attached to the rear of the casing, otherwise you will be able to find the serial number on the lower rear face or on the rear bottom of the left side (below the PTO cover). But even this may not necessarily confirm the ratio, because the gear set may have been changed in the past.

The serial number is found on the lower rear corner below the PTO cover, or just round to the left side.

Changing the high ratio gearing

Most Defenders seem low geared for motorway and main road driving. It’s practical to increase the gearing by around 15 per cent by swapping the gears in the transfer box for a higher ratio Discovery gear set. This only increases high ratio, leaving low ratio as standard, which might be needed for off-road or towing work. But, with Tdi Defenders and especially the earlier (pre-Tdi) Ninety and One Ten models, the engine has to be in good fettle to pull the increased high ratio, and it’s important also to consider the type of use the vehicle will be put to, and whether the vehicle has already been effectively up-geared by fitting oversize tyres. The differences between Discovery and Defender gearing are not straight-cut. For example, the early Discovery Mpi model has a lower high ratio, similar to that of the Defender’s 1.41:1 ratio.

Conversely, the 50th Anniversary Defender 90 (if you’re lucky enough to own one) and the TDCi models have a 1.211:1 ratio, similar to a late Discovery 1 and all Discovery 2 models. There are other anomalies, such as the 2.5-litre naturally aspirated One Ten which has a very low 1.667:1 ratio, in which a Discovery ratio would be too high for heavy towing, given the low engine performance, though an increase to the Defender 1.41:1 ratio might be practical.

Higher gearing is unlikely to provide any meaningful reduction in fuel consumption, so don’t expect a return on the investment, though it will noticeably cut noise levels at speed. A Discovery transfer box can be fitted into a Defender (no point in TDCi which has the same ratio as Discovery), but two M8 holes will need to be drilled and tapped into the casing to accept the Defender handbrake linkage in place of the Discovery’s cable-operated system. If using a Discovery 2 transfer box the diff lock linkage may need to be swapped over if not already fitted.

Discovery gear sets are available from suppliers such as Ashcroft Transmissions. To install a gear set, the transfer box needs to be removed from the vehicle, and it’s wise to consider replacing bearings and seals while the unit is dismantled, for which rebuild kits are available.

Options: increased high ratio (left), standard ratio (centre), and extra low (right) which can counter the effect of larger tyres.

Gearbox spline failure

This is actually a problem with the gearbox mainshaft which engages and drives the transfer box input gear. It was common a few years back, and most of the affected transmissions will, by now, have been rebuilt or at least fitted with the later, improved transfer gear. It is no longer a common occurrence, but worth being aware of on older vehicles. The problem was attributed to lack of lubrication on the mating splines of the mainshaft and transfer gear.

This was sorted in the later R380 gearbox by fitting a transfer gear that was cross-dilled, allowing oil to flow through the drillings to reach the splines. The symptom is a distinct knock from the central transmission area when taking up the drive, but especially if the vehicle was rocked back and forth by moving from first to reverse gear. A knock can be produced by plenty of other components though, including worn radius arm bushes, propshaft universal joints, A-frame joints and bushes. So a good check around is vital before getting worried about the mainshaft. If you hear a knock and suspect the mainshaft splines, investigate by removing the Power Take Off (PTO) cover from the rear of the transfer box. There’s no need to drain the oil before removing the cover, unless you suspect it is over-filled, in which case remove the filler plug first to see if any excess drains out.

If you see rust and fine metal shards in there, the debris will be from the mainshaft’s worn splines. If the vehicle is put into first gear and the handbrake released (on level ground with wheel chocks to prevent excess rolling) you may be able to see the movement by nudging the vehicle back and forth from underneath. The transfer gear can be removed here to inspect the mainshaft splines. The answer is usually a new mainshaft and a new transfer gear (of the cross-drilled type). As this work demands a strip of the gearbox, it’s usually cost-effective to fit a recon gearbox. A gearbox serial number with suffix F suggests a cross-drilled gear is fitted, though many earlier boxes have been retrofitted with the improved gear.

This is typical damage caused to an early LT77 gearbox mainshaft by wear and corrosion of the splines.

Discovery 2 centre diff-lock

Early Discovery 2 models do not have a centre diff-lock lever in the cab because they have electronic traction control (ETC), which eliminates the need for it. Traction control uses the ABS system to lock any wheel that spins, thus preventing all of the torque being transmitted to a spinning wheel. Hence, full torque is always transmitted to the wheels that have grip. Some owners still prefer to have a centre diff lock (which can be retrofitted) on the grounds that it gives a little more driver control and ability in some more extreme off-road situations.

The earliest Discovery 2 models still had the diff lock mechanism fitted but no lever, and a kit is available to install the lever and linkage to operate the existing mechanism. This applies to transfer boxes with serial numbers prefixed 41D and 42D. You can check by feeling the top of the transfer box front housing. If it is smooth, you don’t have the internal mechanism, but if you feel a screwed stud projecting upward, you have the mechanism and just need the lever kit.

For subsequent vehicles that do not have the mechanism nor the lever (diff lock was available as an option when new), Ashcroft Transmissions produce a kit, which includes a new front housing and the necessary parts and seals. This applies to transfer boxes with serial numbers prefixed 61, 62, 69 and 70D. You’ll also need the above lever kit.

If the diff lock mechanism is fitted, you can see or feel the threaded stud rising from the top of the front housing (foreground).

Ashcroft Transmissions supply this centre diff lock kit including a new front housing. A lever will be needed too.

Typical parts and costs

The following parts are available from Ashcroft Transmissions (ashcroft-transmissions.co.uk) and are subject to VAT and, in some cases, a core deposit. It’s also worth checking Ashcroft’s website for their FAQs and gear ratio calculator.

• LT230 transfer box: £495• LT230 rebuild kit: £95• 1.222 gear set: £275• Sleeved (for intermediate pin) transfer casing: £75• Discovery 2 centre diff-lock update kit with new front housing: £225; lever kit: £245.

Problem solving

Stiffer steering:

The steering feels tighter, with more ground effect and feedback. This is a normal effect of driving with diff lock engaged, especially when reaching firmer ground where the tyres are less able to slip to release transmission wind-up. If so, it may be appropriate to come out of diff lock, to reduce the stress on the transmission.

Cannot select diff lock:

The lever moves to select diff lock, but diff lock does not engage and the light does not come on. The linkages may be stiff or seized due to lack of use. If so, it is possible, though fiddly, to clean and lubricate some of the linkage underneath the vehicle and to work the lever for a while to free it off. Otherwise, with the transmission floor cover removed for access, check the lock nut holding the operating arm to the pivot shaft is tight, and that the arm is correctly located on the shaft.

Difficult to disengage diff-lock:

You can feel the steering pull associated with diff lock, and the warning lamp is on, even though the lever has been moved. When disengaging the diff lock it’s often necessary to reverse a short distance. This is a normal feature of the four-wheel drive system. Otherwise, the internal linkage will need to be checked by lifting the transmission cowl to gain access. The switch for the difflock warning lamp, on top of the transfer box front housing, may be incorrectly adjusted, and need screwing out slightly.

Diff lock warning switch is positioned on top of the unit, seen here from the side with cover plate removed, exposing selector mechanism.

Front output flange movement:

The transfer box flange to the front propshaft can be moved up and down slightly. Slight movement can be expected here because there is always slight clearance in the parallel roller bearings supporting this flange, so it is unlikely to need attention. If movement is excessive, or there is an obvious problem, the bearing will need replacement.

If an output flange is grooved here from oil seal contact, fit a new flange, or the grooving will damage the new oil seal.

Whining noise:

Heard generally from the transmission area. Whining is usually bearing noise, and it’s most commonly caused by the axle or final drive (differential) bearings which can transmit along the chassis. So it’s necessary to be sure before blaming the transfer box. The simplest way is to ask a garage to run the transmission on a wheels-free lift while listening underneath for the source of the noise. If the transfer box is the culprit, the wear is likely to be in the front or rear output bearings, or both.

No traction unless diff lock is selected. Expect an axle problem such as a broken halfshaft. If so, with diff-lock disengaged, the propshaft for the defective axle will spin when you let the clutch out.

Oil leaks from front or rear output flange:

Leakage from the rear flange might also contaminate the transmission brake shoes with oil. It’s possible to disconnect the relevant propshaft, remove the flange and replace the seal in situ. When the flange is removed, check the condition of the plain surface of the flange stub where the oil seal touches. The seal can wear a groove, and that damage will quickly destroy a new seal as it rubs against it. If that is the case, fit a new flange with the new seal.

Oil leaking from centre of front face:

Oil can leak from the intermediate gear pin which passes through the front of the casing between the front housing and the gearbox. It has an O-seal, but the pin has likely worn the hole in the casing.

Oil seeping from the transmission brake drum is a sure sign of a failed rear output shaft oil seal.

Avoiding problems

• Check the oil level and change the oil at the intervals prescribed in the service schedule, and do this more frequently if the vehicle is regularly used off road and especially for wading. • At oil changes, inspect the colour of oil that comes out. Grey oil suggests water contamination due to wading. It’s certainly due for changing. The drain plug is magnetic, and will normally have a cluster of fine particles on it that can be wiped off. Large particles or fragments warrant investigation. • Keep a check for oil leaks from gaskets and oil seals, and have them fixed if significant leakage is taking place. • Check that transmission breather pipes are clear and functioning, otherwise there is a risk of oil seal damage and water ingress. • Avoid spinning wheels. When this happens, ease off and engage difflock. Aggressive wheel spins can terminally damage the centre diff. • Taking care of the transfer box, as with any other component is largely a matter of correct00 and timely servicing, attending to problems in good time, and driving the vehicle with consideration for the stress that mechanical components are being put through. Aggressive driving seriously accelerates wear and induces stress.