Not so good vibrations on the Range Rover Sport - pictures

<span>To access the propshaft, the heat shield is unbolted. Use easing oil on threads. Shield may have corroded away around the bolt washers.</span>

<span>To access the propshaft, the heat shield is unbolted. Use easing oil on threads. Shield may have corroded away around the bolt washers.</span>

- Skip advertAdvertisement - Gallery continues below

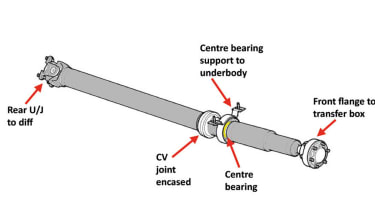

<span>An E12 Torx is used to release the six bolts holding the prop’s front joint to the transfer box, collecting the three spreader plates.</span>

<span>The prop’s rear flange bolts at the differential need an E12 Torx bit. These were very tight – needing the crow bar holding the yoke firmly.</span>

- Skip advertAdvertisement - Gallery continues below

<span>These two 13mm AF bolts holding the centre bearing support to the floorpan are removed, and the centre supported while releasing the end flanges.</span>

<span>The prop flanges are rusted to the transfer box and rear diff flanges, so are tapped and levered free before carefully lowering the propshaft.</span>

- Skip advertAdvertisement - Gallery continues below

<span>With the shaft on the bench, the front and rear U/Js are checked through their full movement. No looseness or stickiness here.</span>

<span>The rubber sleeve bonding the centre bearing in its frame has split, possibly allowing the bearing to whirl. Shaft’s balance weights are intact.</span>

- Skip advertAdvertisement - Gallery continues below

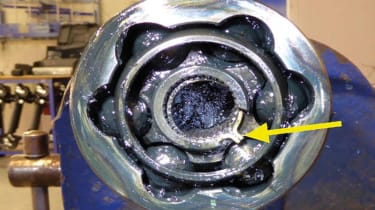

<span>Remove the center bearing: We first need to detach the casing (arrowed) crimped over the CV joint. Front and rear sections of prop are marked to aid re-assembly</span>

<span>The clip is removed from the CV joint casing’s rubber gaiter. Then the casing is opened by tapping it back off the prop using a narrow drift.</span>

- Skip advertAdvertisement - Gallery continues below

<span>Changing to a broader drift, the casing edge is gradually worked over the lip of the propshaft, taking care to avoid damaging the O-seal (arrowed).</span>

<span>The casing is pulled back to reveal a circlip around the splined front half of the prop (in the CV), opened by reaching in with long-nose pliers.</span>

- Skip advertAdvertisement - Gallery continues below

<span>The rear half (with CV) can now be parted from the front section of the prop, then this CV casing is slid off over the shaft splines.</span>

<span>Here is that circlip (step 4). Its tangs (arrowed) were opened to allow the shaft to be pulled out. The circlip is left in position.</span>

- Skip advertAdvertisement - Gallery continues below

<span>After making a note of which way around it is fitted, the centre bearing assembly is carefully prised off the front half of the propshaft.</span>

<span>With the bearing assembly removed, we can see how the rubber mounting has parted company from the frame. The bearing feels reasonably smooth.</span>

- Skip advertAdvertisement - Gallery continues below

<span>FITTING THE NEW BEARING: The new bearing assembly comprises the new rubber mounting, which is bonded to the outer frame and the new bearing in the centre.</span>

<span>Before fitting the new bearing, the prop’s stub shaft surface, on which the bearing locates, is cleaned up with emery cloth.</span>

- Skip advertAdvertisement - Gallery continues below

<span>The new bearing is fitted with its extended collar facing back (toward the splined end). Here it is tapped on square using a tubular drift.</span>

<span>The dust shield, which is supplied with the bearing, is then slid over the shaft with its concave side facing out toward the splines.</span>

- Skip advertAdvertisement - Gallery continues below

<span>Before sliding the CV casing on, the distorted lip around its edge was straightened using grips, and tapped smooth and round.</span>

<span>With reference marks aligned, the splined end of the front shaft is pushed into the CV joint, through the circlip which locks it in place again</span>

- Skip advertAdvertisement - Gallery continues below

<span>Before sliding the casing over the CV joint, fresh CV grease is squeezed in, and sealant applied around the casing’s rubber seal on the prop</span>

<span>With the propshaft supported on a wood block, the CV casing is slid into place and tapped down against and around the propshaft body.</span>

- Skip advertAdvertisement - Gallery continues below

<span>Using a blunt drift, the edge of the CV casing is then peened into the circumferential grove in the propshaft body to secure it.</span>

<span>The securing clip is refitted around the CV casing’s rubber gaiter. Excess sealant is then wiped from between the CV casing and propshaft.</span>

- Skip advertAdvertisement - Gallery continues below

<span>Finally, the shaft is supported in place while bolting the end flanges, before bolting the centre bearing to the body and refitting the heat shield.</span>

- Skip advertAdvertisement - Gallery continues below

Recommended

Best cars for road trips - our top models for the ultimate driving adventure

The best ever popemobiles

New Range Rover Electric ride review: luxury EV could be worth the wait

Top 10 best luxury cars to buy 2025

Most Popular

Car Deal of the Day: 717bhp BMW M5 Touring super-estate on a tasty lease deal

Electric car appeal is at its lowest since 2019

Range Rover Sport SV gets massive £35k price drop as it enters series-production