Blog: Inside a carbon-fibre factory

We get a look around BMW’s new project ‘i’ carbon-fibre plant in Washington

BMW is about to need a lot of carbon-fibre. Both the i3 - which goes on sale in the middle of next year - and the i8, which follows a year later, have entire body cells made from the stuff – and it’s not a cheap material to make, either.

We all know the benefits – it’s up to 50 per cent lighter and stronger than steel and aluminium, it absorbs energy brilliantly in an accident (any Formula One driver who’s had a high-speed smash can verify this one) and doesn’t corrode and fatigue like metal. But high costs and lengthy manufacturing times have limited its use to hi-end cars like McLarens and Lamborghinis.

BMW is planning to change all that, though, by manufacturing carbon-fibre-reinforced plastic components from scratch, and en masse, in a series of dedicated plants dotted around the world. We had the opportunity to visit a brand-new $100m factory – a joint venture with carbon-experts SGL – in Moses Lake, Washington, where spools of carbon-fibres are produced before being shipped back to Germany and turned into parts.

“Once both production lines are in place, we’ll make around 3,000 tonnes of carbon fibres a year - around 8 per cent of the world’s total production - and there’s space for four more lines on the existing site and an option to buy 60 acres more,” Dr Joerg Pohlman, managing director of the BMW-SGL partnership, told us.

A crucial competitive advantage for BMW is the intelligent positioning of the Moses Lake plant. Located nearby on the Columbia River are two enormous hydroelectric dams, which supply 100 per cent of the factory’s substantial energy requirements at just three cents a kwh – a quarter of the normal price. “This cheap, sustainable energy is the difference between being it making financial sense and not,” Pohlman admitted.

Inside the factory itself, the production line has more in common with the textile industry than cars. It begins in the creel area where boxes of 40km long 100-strand strips of precursor (a by-product of crude oil imported from Japan) are fed onto rollers and ‘combed’ into neat 50-strand strips. From here they are fed through a series of six increasingly hot ovens, which first oxidise and then carbonise the glossy strands, turning them from white to jet-black.

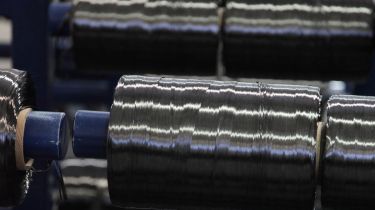

The material is then shocked in a high-voltage bath to rough up the edges and coated in a light resin before being rolled onto 9kg spools. These are then shipped to another factory in Wackersdorf, Germany, to be knitted and shaped into the 30 parts that, once glued together, make the i3’s passenger cell.

“Our goal is to match the cost of aluminium,” Pohlman revealed. “We’re not there yet, but compared to the carbon currently used in the roof of the M3, the new material we’ll use in the ‘i’ cars is a third of the price to produce.”

Find a car with the experts